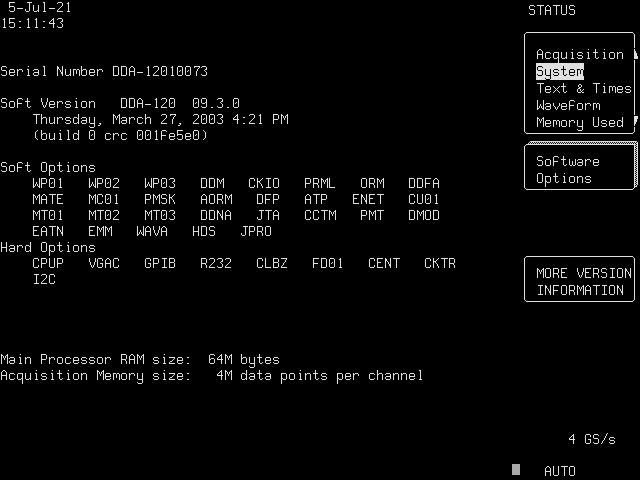

You can see I have added many options of this scope (>95% full). The information can be found in EEVblog and look in below link reply #85. The difficult part is for me to install Python2.7.18, Visual Basic for Python2.7 and PyCrypto in my Windows 10 PC to run the Python scripts.

https://www.eevblog.com/forum/testgear/lecroy-options-recovery/75/

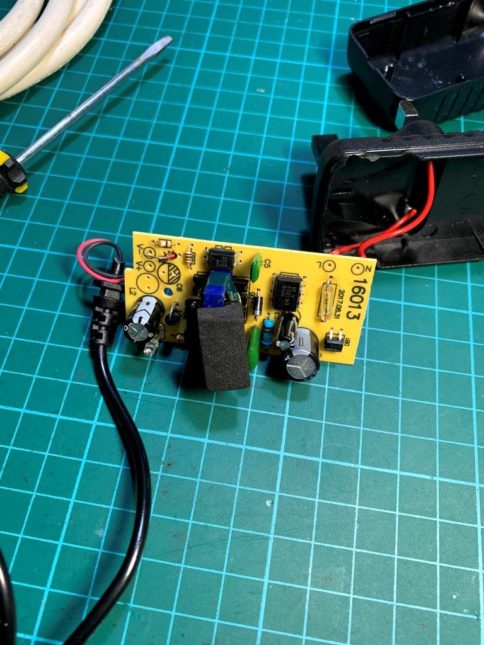

- Power supply is leaking due to RIFA PME271 capacitors (4 pcs in supply filter circuit) leaking (body crack). Change to other type High voltage safety capacitors to prevent leaking. Also -15V supply is not stable and I replace U3B LM358 op-amp by normal JRC5532 to resolve the issue. +15V supply retune and get back +15V from 8.xV. The supply design is not really good as it use some TO-220 power transistor and load resistor to drain the power supply to get the rated voltages but if the supply is not connected to nominal load, then it may be over-voltage a bit and loading transistor will be super hot!

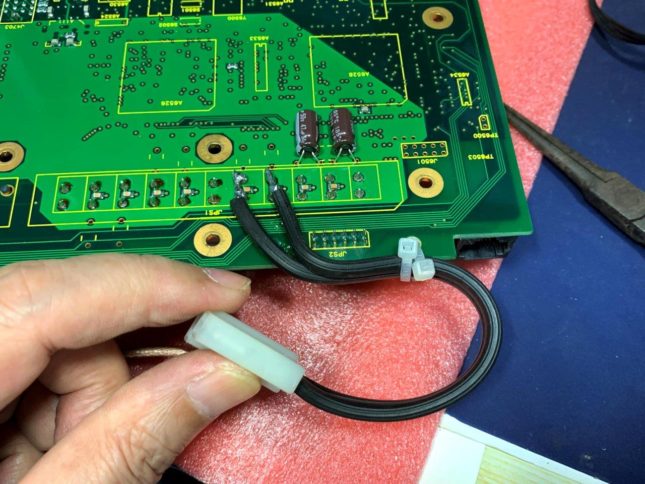

- The connector from power supply -5V is oxidized and darken and thus bypass wires are added with plug & socket for both +5V and -5V to ensure good conduction.

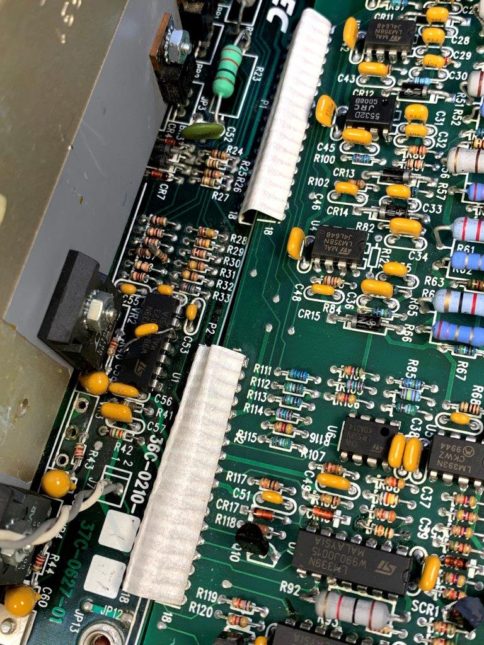

- The regulator also has two jumper wire cables for connection and I found that these single strand wires are very easy to break (brittle) and thus I changed them to Telfon stranded wires to increase the flexibility & reliability. Reasons was that I experienced the +/- 6V from regulator loss its regulations and output +/-12V to the main board due to jumper connection open or intermittent!!! This will make the scope cannot acquire signals and relay keep on clicking with channel 2 missing trace, cannot reset scope and offset adjust unstable. Very danger to further damage the main board if not power off immediately.

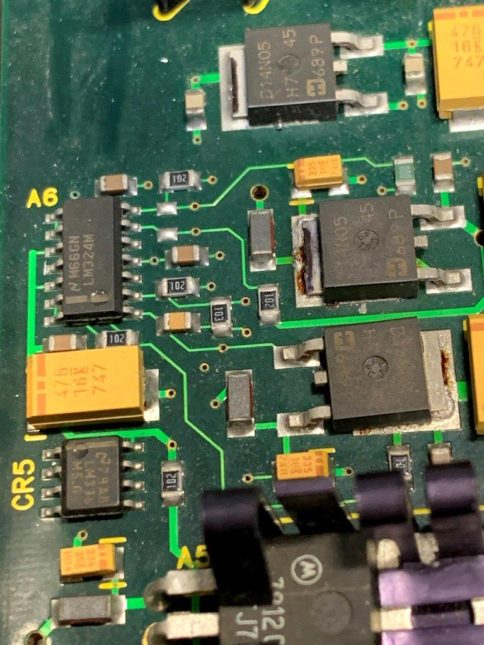

- After the supply issue on +/-6V become +/-12V, I found there are two Mosfets (D14N05) on the main board become brownish and solder joint looks overheated. The symptom is that the scope failed like item 3 after warm up a while. Thus I re-solder them again on the PCB to resolve the issue. Photo shows that the solder is a bit melt with darken flux residue mark and looks like cold solder joint!

- I use Agilent 82357B GPIB adaptor and after install the driver, MUST enable the IEE488 function or else it cannot work due to default to Keysight equipment only!

- Battery is replaced with same type rechargeable (about US$8).

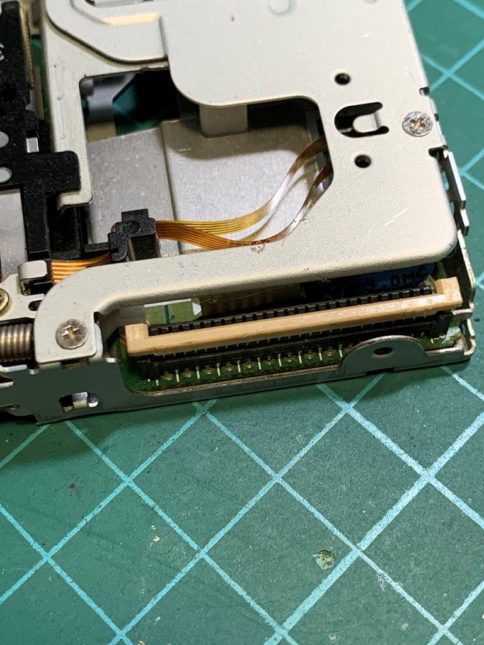

- Floppy drive is also replaced. I own an old no brand USB floppy drive about 10 yrs ago (IBM brand USB floppy is pure USB design main board; Non IDE version) and open up see that there is a USB to IDE converter PCBA. In fact the drive is an IDE floppy + USB convertor board and the connector 36 pins just fit into the original mounting kit, excellent! I need to cut and filing away some plastic on the front panel and also glue the original plastic front cover on to the front panel to fit, looks quite nice!

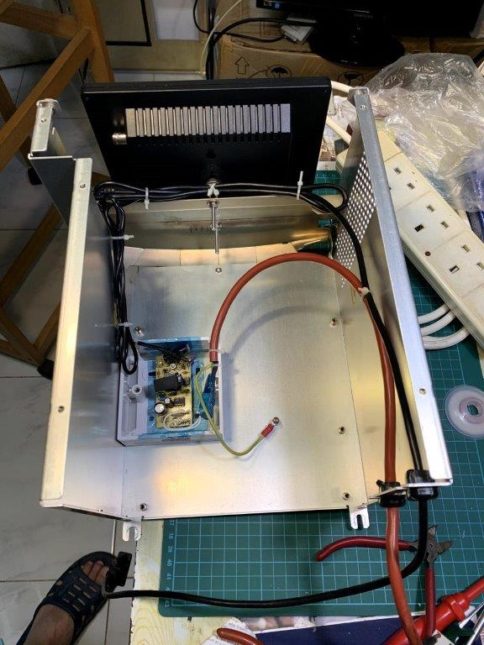

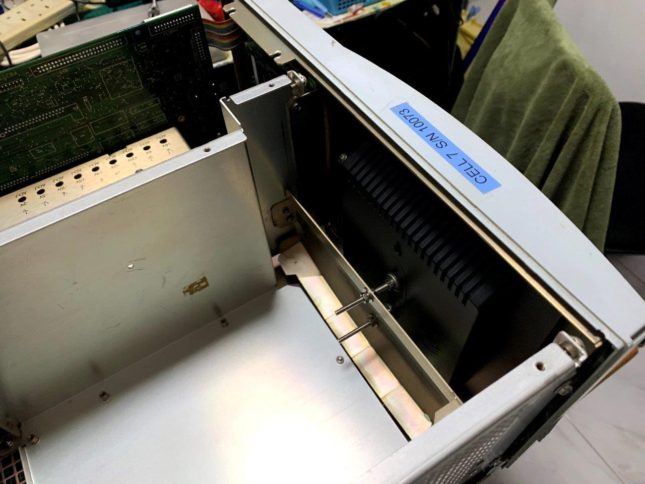

- I have changed the display from picture tube to LCD monitor! The LCD monitor only costed me US$30 and all E-caps are upgraded to Panasonic FC in both LCD main board and the AC adaptor. Note that the monitor need to be 8 ~ 9 inches screen size with 4:3 aspect ratio and VGA input must be compatible with resolution 640×480. Picture show how the LCD is installed using the bottom curved metal frame for mounting the LCD monitor back by drilling two holes on each side to secure in position. Two long screws are used to support the back side of the LCD monitor slot and mounted at the center of the curve metal frame. LCD monitor power Adaptor is open up, changed all E-cap to better grade and put the PCBA in an electrical plastic box for better cooling. Original power cable is used and monitor VGA cable from monitor is routed through original back hole positions for connection to Power Switch point and internal VGA out.

- The display metal box is totally re-used and put back into the scope same position. This is necessary as the mechanical strength is maintained for the chassis especially the front panel mountings! I added a PP sheet at the back of the TV box to block all the holes there for TV section air circulation. Thus the internal airflow for big fan is now mainly from the bottom main board (believe a bit better than before). Overall the fan noise is still there and I added some acoustic foam behind the LCD monitor as shown and it can reduce a bit the fan noise!

- The thermal printer is still working but I feel there is no need to keep it and I totally remove it and use a plastic sheet to cover up the top rectangular hole to ensure air flow is same as before. So in total I can reduce the scope weight by almost 5kg and consume less 100W power!

- Serial number is re-written by Lecroy Explorer (Use “**SY_NO xxxxx”, one space after letter O) and firmware 9.3.0 is updated to the scope. Here I thank you very much the “LeCroy Owners’ Group” for providing all the service manuals and necessary information at below link. Without the group, my repair may not be successful! https://groups.io/g/LeCroyOwnersGroup

RIFA capacitors on main filter board with crack lines

RIFA cap with cracked body and verified leaky

Corrosive -5V darken pin with poor connection

Main board bypass wires connection method before apply hot glue

Power supply added two wires and socket for +5/-5V

After replace jumper wires

Original single strand jumper wires (note one regulator chips is removed for testing)

Three mosfets with two solder look cold and flux residues burnt

GPIB working

Batter changed

USB to IDE converter board

New floppy connector

New floppy mounted on original frame

Final floppy view

LCD monitor driving main board capacitors

Front view of LCD monitor

Centre mounting screws and nuts

Original LCD monitor power adaptor

Routing of the power cable and VGA cable

LED monitor adaptor PCBA mounted on insulation box

Curve bracket mounted on Tube monitor box frame

Centre mounting screws for monitor

Acoustic Form added behind LCD monitor

LCD Monitor instead of picture tube display